Industrialization

SOLUTION

INDUSTRIALIZATION

Precision Aerospace Components

Crafting Excellence with 5 - Axis Precision

Welcome to AIR MED AVIATION, where precision meets innovation in aerospace manufacturing. We understand the criticality of precision, reliability, and safety in the aerospace industry. Today, we will showcase how our utilization of advanced technologies, such as 5-axis machines and 3D control machines, enables us to deliver aircraft of the highest quality standards.

AIR MED AVIATION we are pioneers in crafting precision aircraft parts, our commitment to excellence has propelled us to the forefront of the aerospace industry.

Overview of Precision Aircraft Manufacturing

Precision aircraft manufacturing presents unique challenges. The aerospace industry demands parts that meet extremely tight tolerances and strict quality standards. Our factory is committed to achieving these requirements while ensuring our aircraft's reliability and safety. Precision is the core essence of our manufacturing process.

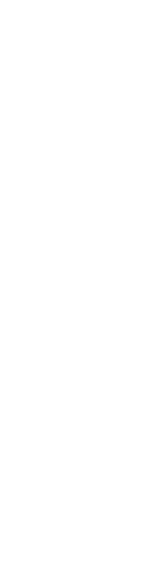

Unmatched Precision with 5-Axis Machines, our state-of-the-art 5-axis machines enable unparalleled precision, ensuring that each component meets the highest standards of accuracy

5 Axis Machines in Aircraft Manufacturing:

Our factory relies on 5-axis machines to empower our production process. These advanced machines offer us the capabilities to perform complex machining operations and manufacture intricate part designs. By utilizing 5-axis machines, we can achieve higher efficiency, reduced setup time, and superior accuracy. Engine components, structural parts, and other critical aircraft elements are manufactured with utmost precision using 5-axis machines

Cutting-Edge Technology: Our factory relies on 5-axis machines to empower our production process. These advanced machines offer us the capabilities to perform complex machining operations and manufacture intricate part designs. By utilizing 5-axis machines, we can achieve higher efficiency, reduced setup time, and superior accuracy. Engine components, structural parts, and other critical aircraft elements are manufactured with utmost precision using 5-axis machines

advanced 5-axis machines redefine precision engineering.

STRUCTURAL PARTS

BEAMS

Air Med Aviation has a number of 5-axis machines which it uses to produce light alloy and hard metal beams under optimal production conditions.

DOOR PARTS

The company has high-performance milling and turning equipment to produce the precision parts used in door mechanisms.

FITTINGS

Fittings are small parts made of lightweight alloys or hard metals used as supports or as complements to larger parts.

DE-ICING PANELS

Air Med Aviation is able to manufacture parts with very demanding specifications, such as de-icing panels.

FLAPTRACKS

Flaptracks are parts used to build wing flap adjustment mechanisms.

WINDOW FRAMES

Air Med Aviation specialises in the machining and surface treatment of aluminium window frames at its production sites.

ENGINE

AND PRECISION PARTS

BLADES

Air Med Aviation has the machine tools and surface treatment capabilities required to produce various sizes of metal blades of different sizes for all known engine production programmes.

LUGS

Lugs are technical parts made of hard metal and used as component parts for engine pylons. They are used to fasten elements such as rods to the engine.

LANDING GEAR PARTS

Air Med Aviation has the resources and expertise needed to produce precision parts of very high quality.

SUB - ASSEMBLIES

ACCESS DOORS

ENGINE ENVIRONMENT SUB-ASSEMBLIES

Air Med Aviation provides assembly services for engine parts including the installation of fasteners, pins and rings.

STRUCTURAL PARTS

The goal is to further improve the surface of parts after machining to ensure that they provide optimal protection against corrosion and wear and tear throughout their life cycle. Types of special processes and treatments for aluminium, titanium and steel alloys:

Degreasing

(alkaline-based cleaning),

Degreasing

(alkaline-based cleaning),

Chemical machining,

Chemical machining,

Heat treatment,

Heat treatment,

Colourless and coloured anodising:

Colourless and coloured anodising:

CAA

(Chromic Acid Anodising),

CAA

(Chromic Acid Anodising),

SAA

(Sulfuric Acid Anodising),

SAA

(Sulfuric Acid Anodising),

TSA

(Tartaric-Sulphuric Acid Anodising),

TSA

(Tartaric-Sulphuric Acid Anodising),

PAA

(Phosphoric Acid Anodising),

PAA

(Phosphoric Acid Anodising),

BSAA

(Boric-Sulfuric Acid Anodizing).

BSAA

(Boric-Sulfuric Acid Anodizing).

Passivation,

Passivation,

Sand blasting,

Sand blasting,

Shot peening,

Shot peening,

Polishing

Polishing

more about

Industrialization

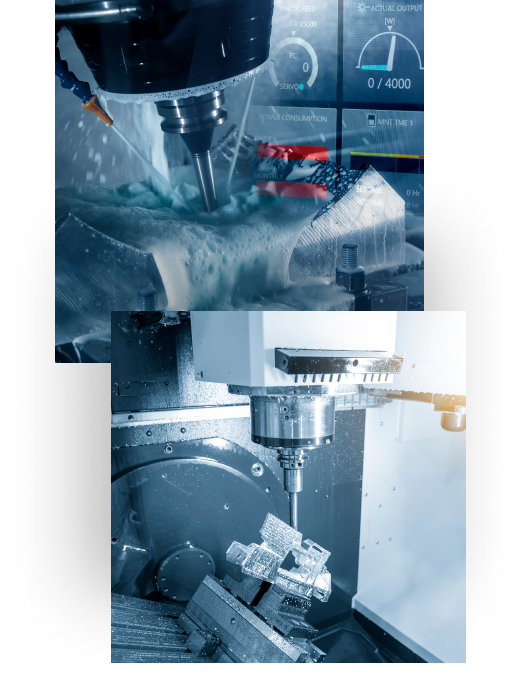

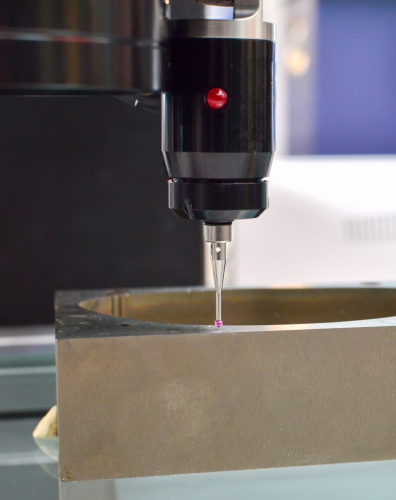

3D Control Machines for Quality Assurance:

Quality assurance is paramount in our manufacturing process, and we employ 3D control machines to ensure our aircraft's precision and accuracy. These machines enable us to perform dimensional inspections and verify the conformity of every single component. The utilization of 3D control machines provides numerous advantages, such as faster inspections, enhanced accuracy, and improved overall product quality. By minimizing errors, we can guarantee exceptional performance and safety in our aircraft.

Setting the Standard for Excellence, our commitment to quality is ingrained in our processes. Rigorous inspections and adherence to industry standards guarantee components of the highest caliber.

Integrated Workflow and Process Optimization:

At our factory, we have implemented an integrated workflow that seamlessly combines 5-axis machines and 3D control machines. This integrated approach allows us to streamline our production process, resulting in improved efficiency, reduced lead times, and ultimately, increased customer satisfaction. We continuously optimize our processes and leverage automation to enhance productivity and quality control. Data obtained from 3D control machines play a central role in our process improvement initiatives.

From concept to completion, from initial design to the final product, we offer comprehensive solutions. Our integrated approach ensures a seamless and efficient manufacturing process.

Skilled Workforce and Training:

Our factory acknowledges the paramount importance of a skilled workforce in precision aircraft manufacturing. We provide continuous training programs to our employees, enabling them to acquire and enhance the expertise required for operating 5-axis machines and 3D control machines. By investing in our workforce, we ensure that our factory remains at the forefront of technology and can manufacture aircraft to the highest standards of precision and quality.

CONTROL

AND QUALITY

The Quality of production is our top management priority. AIR MED AVIATION earmarks significant human and organisational resources to guarantee quality of the production. All employees are involved in the quality process to ensure customer satisfaction.

Significant resources are deployed, ranging from visual inspections to dimensional and three-dimensional inspection of parts.

All the manufactured parts are checked by high quality instruments and machines applying strict procedures that allow the constant control of the state of calibration of machines and used tools

GET IN TOUCH WITH US

Feel free to reach out to us with any inquiries or requests by clicking the 'Contact Us' button below. We are here to assist you.