Complex Component Production

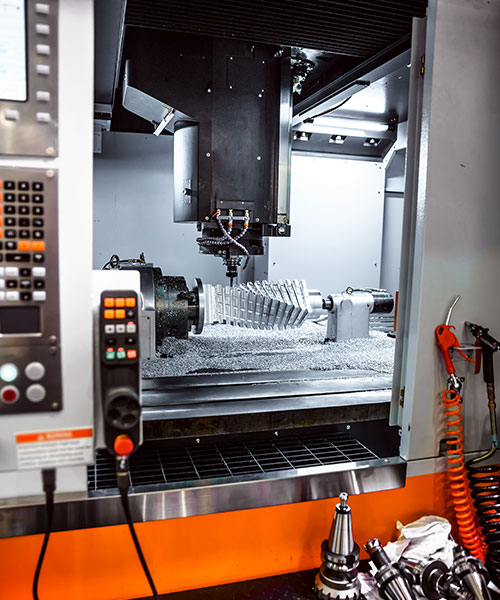

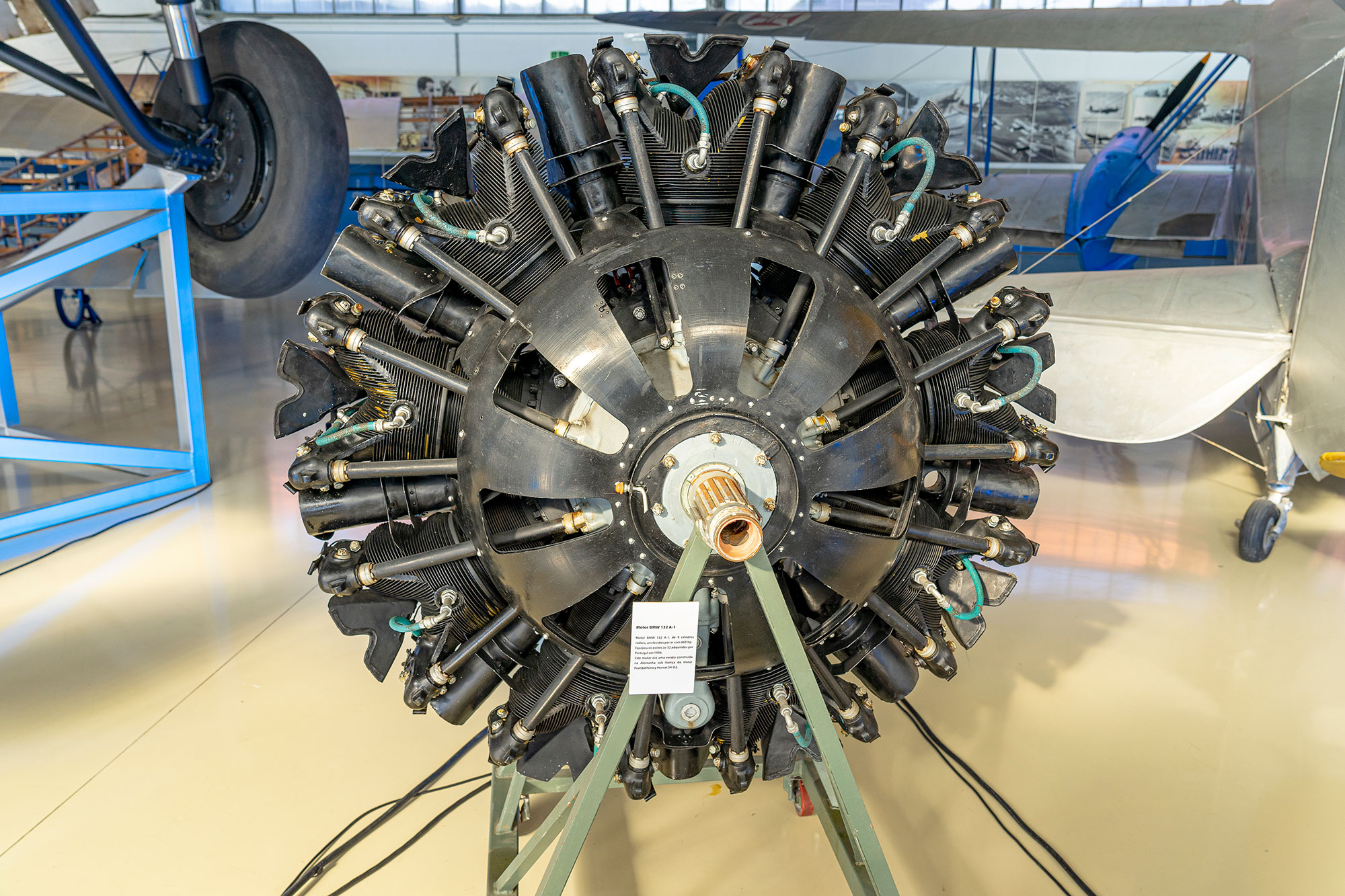

At Air Med Aviation, we specialize in the precision manufacturing of complex aerospace and aircraft components, offering solutions tailored to the most demanding geometrical, structural, and functional specifications. Our state-of-the-art facility is equipped with advanced multi-axis CNC technology, including 5-axis and 9-axis machining centers, allowing us to craft highly intricate parts with exceptional accuracy, ultra-tight tolerances, and superior surface finishes.

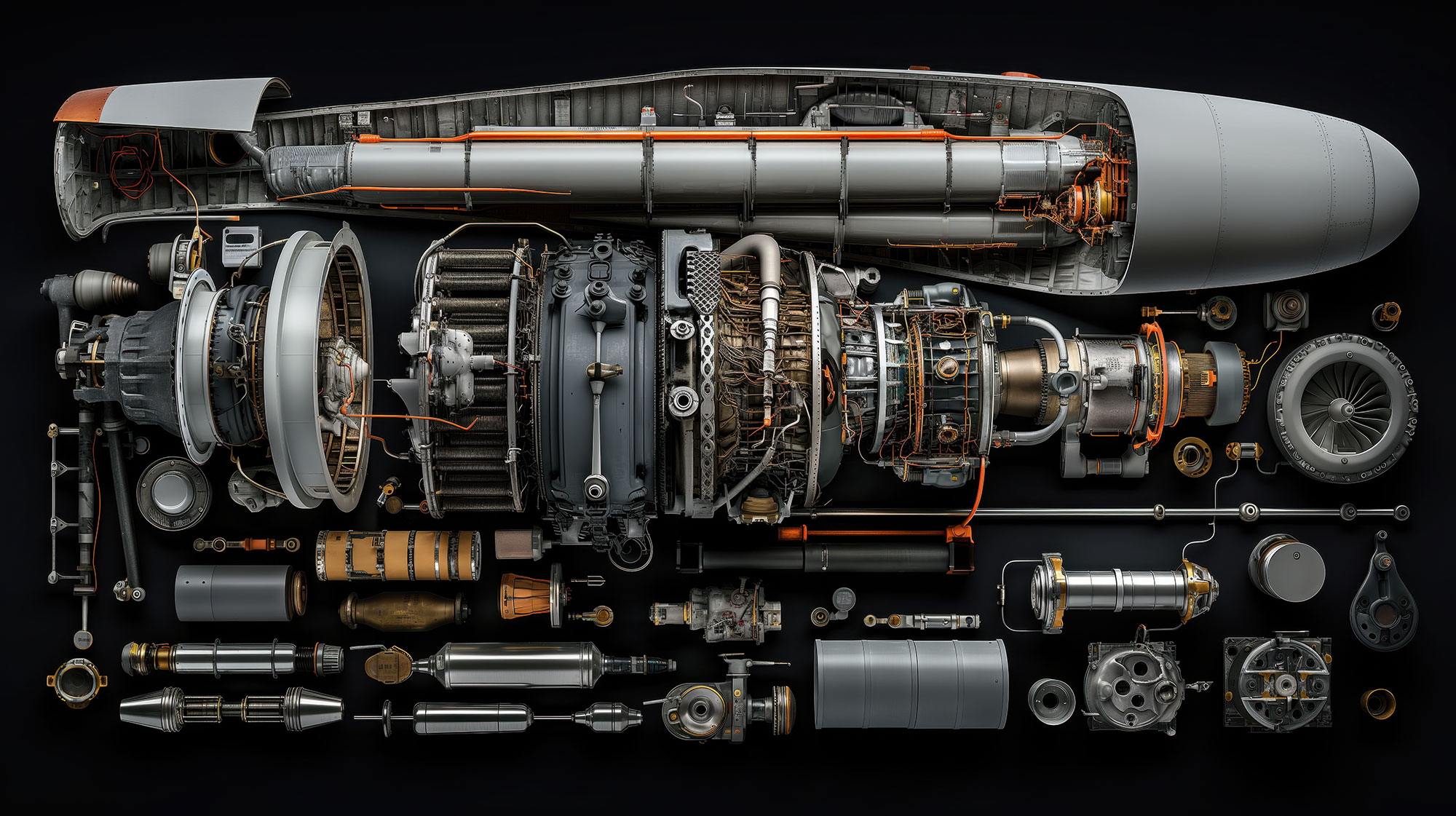

From critical engine components and airframe structures to interior mechanisms and high-performance assemblies, we deliver parts that align perfectly with your design intent—no compromises. Our engineering and production teams work hand-in-hand to tackle challenging geometries, complex materials, and sophisticated assembly requirements with speed, precision, and efficiency.

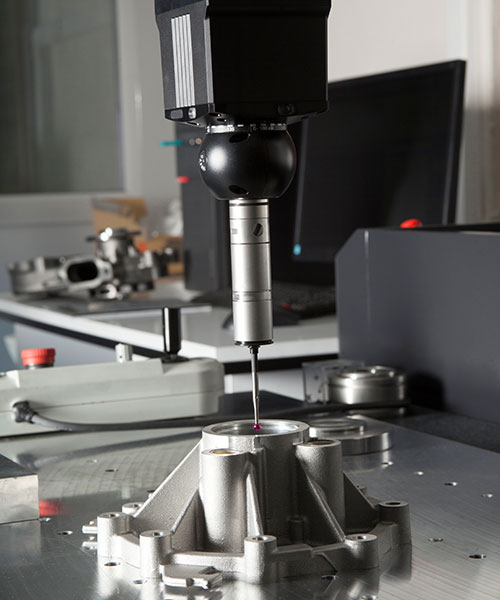

What sets us apart is not just our technical capabilities but our unwavering commitment to quality. Every part undergoes rigorous in-process and final inspections, supported by CMM (Coordinate Measuring Machine) verification, material traceability, and documentation that meets the highest aviation and regulatory standards including AS9120, ISO 9001, ASA-100, and FAA AC 00-56.

Whether you require prototyping, small batch, or high-volume production, we ensure consistent results, on-time delivery, and full compliance—making us a trusted partner in your supply chain. With Air Med Aviation, you gain not only a supplier, but a team dedicated to performance, reliability, and long-term success.

Certificates Quality

We benchmark our quality against the highest international standards to ensure that our clients receive world-class quality services. Air Med Aviation has been awarded certificates from

Air Med Aviation services comply with FAA, EASA, and other international regulatory authorities.