Custom Machining

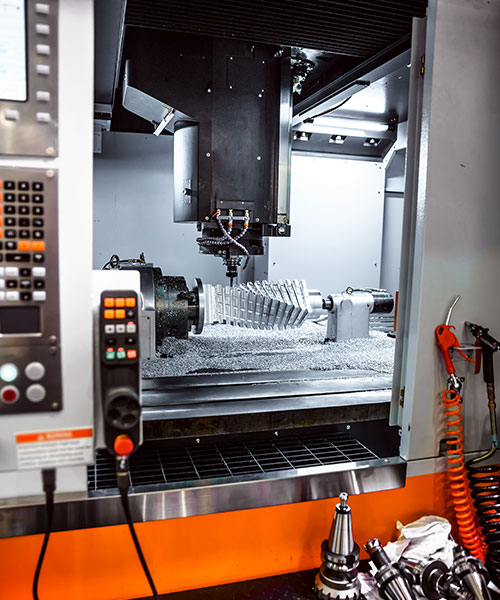

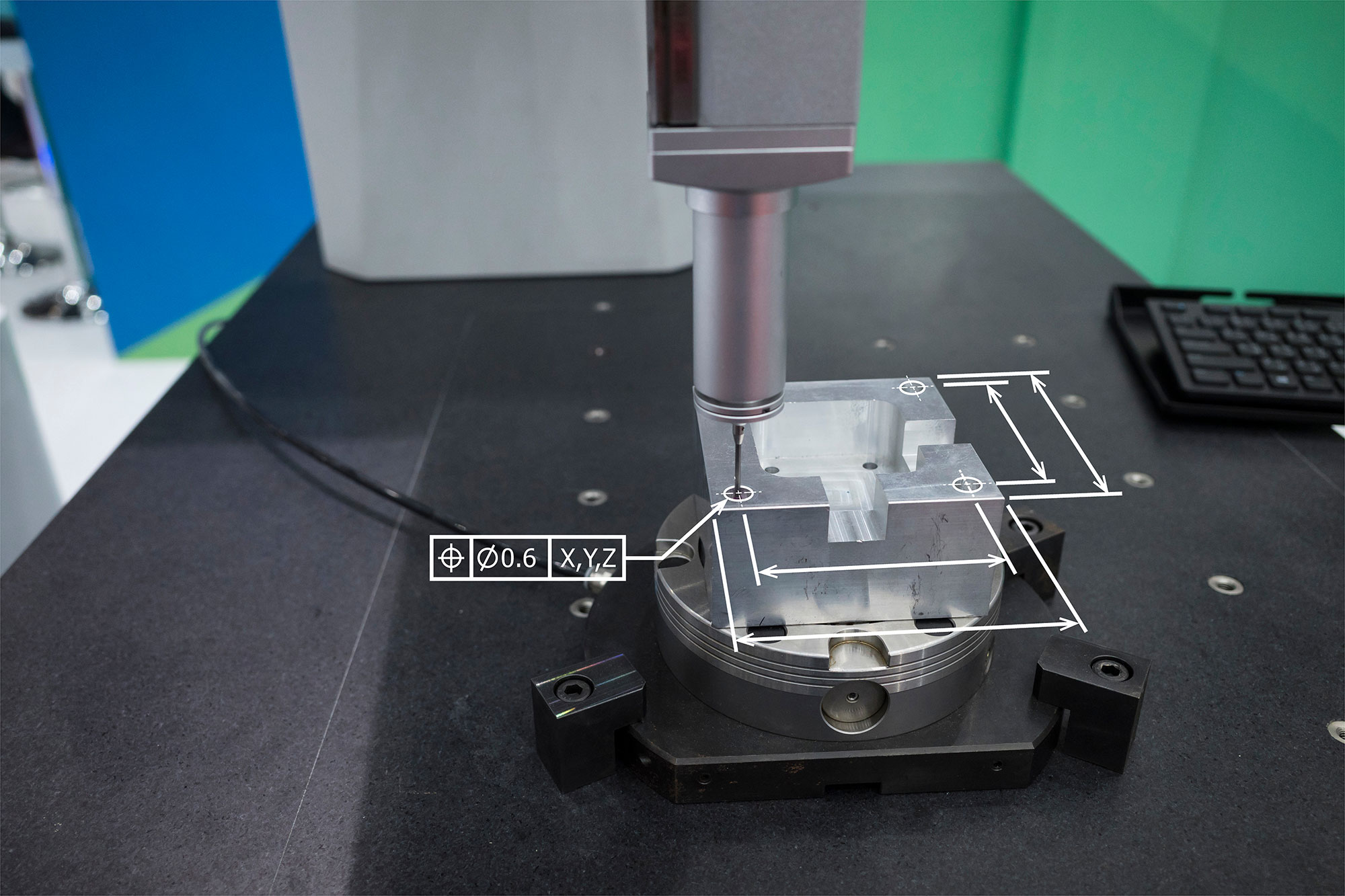

At Air Med Aviation, offers advanced custom machining solutions that meet the highest standards of the aerospace and aircraft industries. Our manufacturing facility is equipped with state-of-the-art CNC 5-axis and 9-axis machines, enabling us to produce highly complex, multi-surface components in a single setup. This reduces cycle times, increases consistency, and ensures precision even in the most geometrically demanding parts.

We also operate CNC laser cutting machines, allowing us to cut aluminum alloys and other aerospace-grade materials with exceptional edge quality, minimal heat distortion, and tight tolerances.

Our machining processes are optimized for materials commonly used in aerospace, such as aluminum, titanium, and other high-performance alloys. Every operation is performed by trained and qualified personnel, supported by strict quality protocols and in-process inspections. Our engineering team collaborates closely with clients during the design and development phases, offering DFM (Design for Manufacturability) advice to enhance efficiency and reduce lead times.

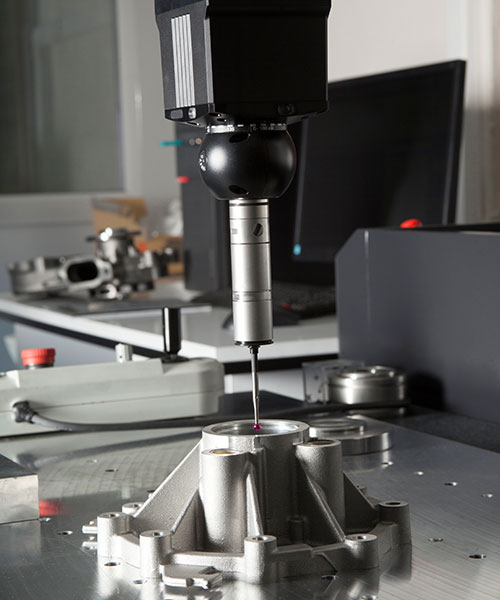

Each part undergoes process capability analysis, tooling validation, and first article inspection FAI per AS9102 standards. From precision brackets, fittings, and housings to custom-engineered structural components, we deliver parts that are ready for integration in critical aerospace systems. Whether for prototyping, production, or urgent repairs, Air Med Aviation is committed to providing responsive service, technical expertise, and dependable results that meet both regulatory and client-specific standards.

Certificates Quality

We benchmark our quality against the highest international standards to ensure that our clients receive world-class quality services. Air Med Aviation has been awarded certificates from

Air Med Aviation services comply with FAA, EASA, and other international regulatory authorities.